Nuclear-armed, Soviet ballistic missiles were a recurring nightmare for late 1950s-vintage NATO planners. The Alliance depended on miles of US-laid concrete runways for reinforcements and much of its striking power. Given the fact that these runways were concentrated at a few precisely surveyed installations in Germany and the UK, their concern remains understandable. At the same time, Korea showed that high-performance, state-of-the-art fighter aircraft would have to be capable of operating out of rough, front-line airstrips. Western air forces could no longer to rely on tractable, WW2-era, piston-engined fighter-bombers for close support once an enemy had committed his most advanced jets over one of the world’s most backward countries.

The relatively conventional NATO light-weight fighters like the FIAT G.91 and the Folland Gnat were one answer to this dilemma. The radical Harrier was another. The SE5000 series fell somewhere in between. The nationalized SNCASE company (an ancestor of Aerospatiale) set out to produce a conventional, swept-wing, transonic fighter-bomber that could operate out of pastures and plowed fields too rough for many propeller-driven aircraft. SNCASE (later shortened to Sud-Est) assigned the problem to its talented, Polish chief engineer, W. J. Jakimiuk, formerly chief designer of Poland’s PZL firm and, later, creator of the DHC Chipmunk trainer.

Jakimiuk saw that the problems framed by the requirement all turned on the landing gear. The high power required for short takeoffs from poor surfaces could be provided by rocket-assist. But the aircraft would need a hefty undercarriage and bulky, low-pressure tires just to survive the pounding of a rocket takeoff. Short landings were even more demanding, since the undercarriage would have to support high sink rates and powerful brakes. Such an undercarriage would, Jakimiuk realized, bite deeply into the fuel and weapons payload, given the available engine power and fuel consumption typical of the period. Even if the landing gear could be built (no easy task in itself), the compromises would be so great that the aircraft would not appeal to air staffs (consider the USN and USAF attitude to Harriers for example).

Jakimiuk decided that the seemingly insoluble problem set by the specification would disappear once it was recognized that there were, not one, but two distinct difficulties, each demanding its own solution. At takeoff, when the aircraft was heavily loaded, low rolling resistance and soft ride were at a premium. Big, soft tires and a compliant suspension were essential. But the moment the aircraft left the ground, these desirable features became so much dead weight. During the landing run, high rolling resistance was actually desirable, since it relieved the strain on the brakes. A highly compliant suspension was now undesirable, because it promoted bouncing, lengthened the landing roll, and increased the risk of ground looping. Jakimiuk’s solution was, in some ways, obvious. He made the undercarriage detachable. During WW2, the Me 163 rocket fighter and the early models of the Ar 234 reconnaissance bomber had used jettisonable takeoff trolleys and light, compact landing skids in place of normal struts, wheels, and tires. Starting where they left off, the SNCASE team refined the design to eliminate the idea's main weakness: the immobility of the aircraft after landing and before retrieval.

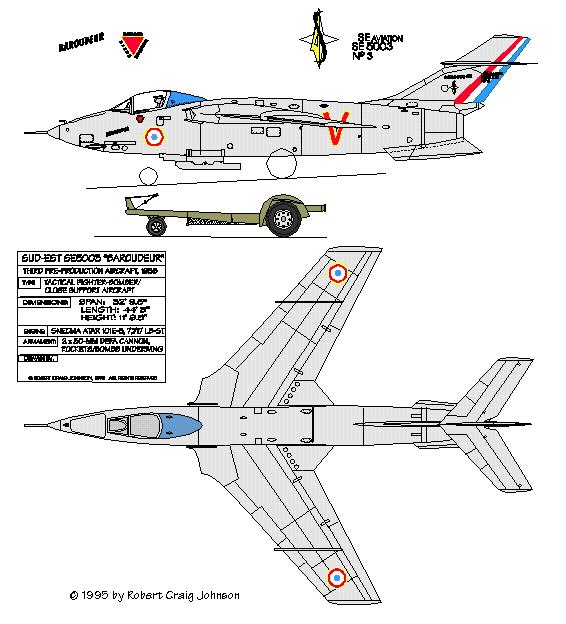

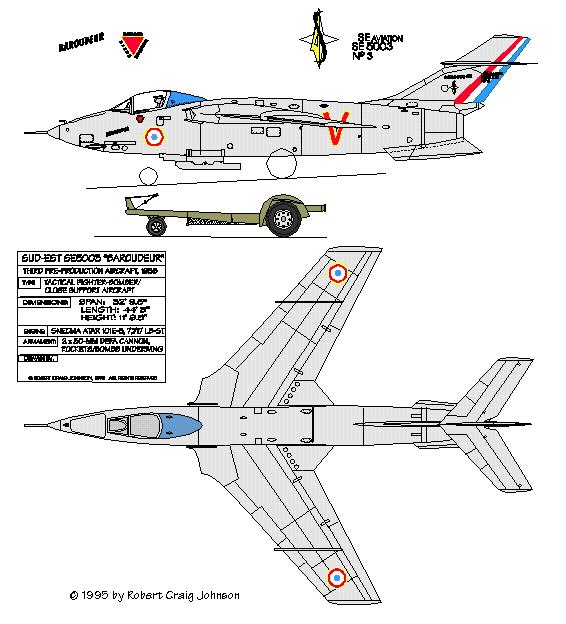

The SE 5000, as the new design was called, would take off from a rocket assisted trolley, much like the Ar 234. But the Baroudeur's trolley would have a high-compliance, big-wheel suspension for better rough-field performance. The skid arrangement would also be much more refined. So much so that the SE5000 prototypes proved perfectly capable of moving about on their twin tail skids/ventral fins and twin retractable main skids. They could taxi up to a Jeep-towed trailer, which would then winch them in under two minutes. Indeed, under ideal conditions, the aircraft could even take off using the skids alone. Yet the skid arrangement easily handled the shocks encountered in landing and stopped the airplane very rapidly indeed. The SE5000s proved able to operate from ploughed and unploughed fields, sand and gravel beaches, muddy pastures, and patches of frozen ground as short as 750 yards.

In other respects, the Baroudeur (a slang term for a Foreign Legionnaire, meaning "Brawler") was a conventional warplane of the period. The wing spanned 32 ft 9.5 in and was swept at 38 degrees. Two 30-mm cannon resided in the nose, either DEFA or the more powerful Hispano 603. Fuel tanks, rockets, bombs, and napalm tanks could be carried underwing.

The first SE 5000 first flew 1 August 1953. Results were good enough that the French government ordered three developed, pre-production machines under the designation SE 5003. The modest power of the Atar 101C (later 101E in the three pre-production machines) could push the airplane to just above Mach 1.0 in a shallow dive. The SE 5003s passed extensive operational testing with flying colors. But a combination of politics and budget problems led to the cancellation of the airplane. Conventional F-84 Thunderjets and F-84F Thunderstreaks were bought instead under easy, American terms. The illustration shows the markings and general arrangement of the third pre-production airplane.

© 1995 by Robert Craig Johnson. Part of a series first published in Eagle Droppings, the Newsletter of the Rocky Mountain Chapter, IPMS/USA.